Description

The electric pumps of the D series are submersible units specially designed for hard work in the lifting of dirty water without supervision.

Solves all bilge problems, even if the water contains mud, sand and others.

They consist of a hydraulic part and an electric motor.

The design has sought both robustness and lightness.

The D electric pumps are groups of a great solidity and safety, thanks to their bearings and oversized shaft, probes of humidity and temperature (of series from 7,5 Cv), double mechanical seal, and oil chamber to lubricate the mechanical seals and to protect of the filtrations of water.

Paint treatment by means of a double epoxy layer, reticulated with special polyamide for immersion and aggressive industrial environments.

All groups have three-phase squirrel cage type electric motors. Powers range from 1.5 Có to 20 Cv.

For high-rise installations, several units can be installed in series.

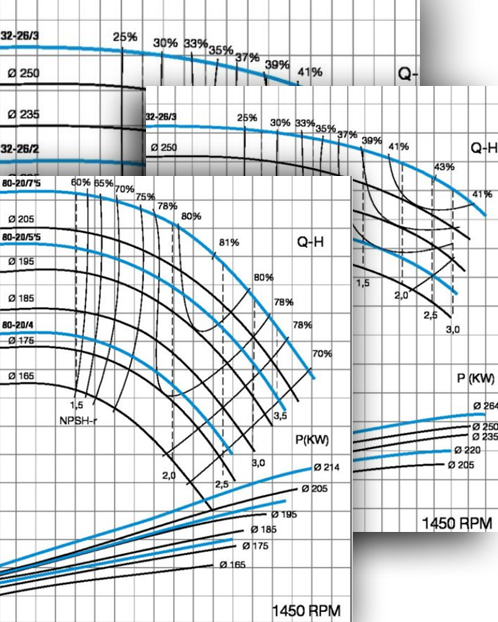

To select a submerged group, the following parameters must be taken into account:

- Manometric height

- Flow

- ph and electrical conductivity.

- Density and viscosity of the liquid to be pumped

- Application

- They don’t need to be fattened.

- They can work dry in short periods of time.

- They do not require the installation of piping, sufficient with a hose.

- They can operate day and night without interruption or danger.

- They don’t need a foot valve.

- They don’t need lubrication.

- Easily transportable due to its low weight.

- Wear parts can be serviced quickly and easily on the job site without the need for specialist mechanics

- Keep excavations dry.

- Construction

- Drainage and water depletion in mines.

- Drying of formwork, trenches and channels

- Desiccation of wells

- Vessels

- Wastewater treatment plants

- Pumping of municipal and industrial wastewater.

- Drainage of buildings and land.

- Industrial processes.

- Rainwater containing abrasive particles and sands

- Quarries

- Decanting of dirty and loaded waters, containing crushed filamentous bodies.

- Black wells

- Collection of biological pits.

- Pump body – ZL 104

- Impeller – ASTM A4746 CA40

- Body Cover – ZL 104 GG25

- Engine housing – GG-25

- Stainless steel shaft – Aisi 420

- O-rings – Nitrile (Optional viton)

- Screwsinox – Aisi 316

- Maintenance-free, permanently lubricated bearings

- Mechanical seals – Silicon carbide viton

- Painting – Epoxy

- Electrical connections on rail (DIN)

- Electric cable – Neoprene H07RB/7

- High efficiency three-phase electric motor, squirrel cage type, IP68 protection, insulation class F and H

Submersible electric pumps designed to lift dirty water.

INSTRUCTION MANUAL

Call us

Send us an email